产品详情

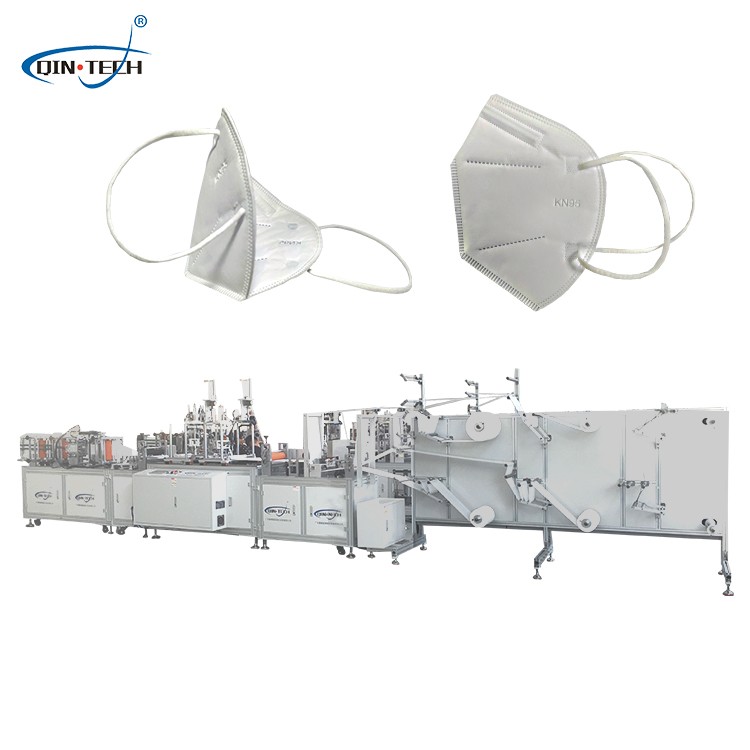

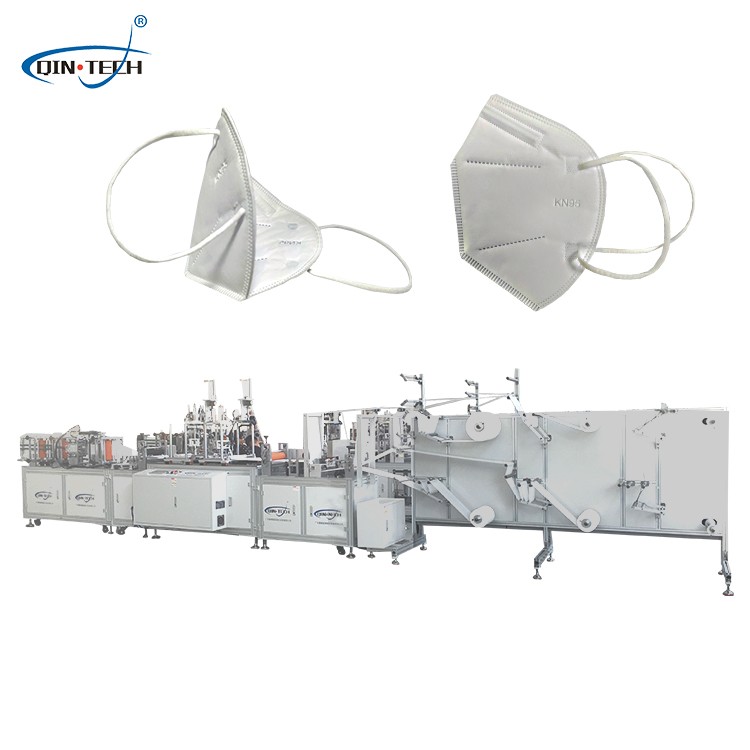

全自动KN95折叠口罩一体机 N95口罩生产线

一、设备工艺流程

N95全自动折叠口罩一体机是用于生产折叠口罩生产线的全自动机器,采用超声波技术,将3~6层PP无纺布、活性炭滤材以及过滤材料等部品进行熔接。整套设备经过无纺布熔接,耳带熔接、印刷、对折、封边、滚切等一体化全自动折叠生产工艺,可加工3M 9001、9002等和其它折叠口罩。根据产品需求所选用的原材料可以生产出达到如FFP1、FFP2、N95等不同的标准的口罩,全程生产无需人才参与,全自动完成生产成品。

自动放卷——鼻梁条送料——超声波熔接——LOGO移印——耳带焊接——折叠成型——超声波焊接裁切+成品输出

1. Equipment process

The N95 automatic folding mask individual machine is a fully automatic machine used to produce a folding mask production line. It uses ultrasonic technology to weld 3 to 6 layers of PP non-woven fabric, activated carbon filter materials and filter materials. The whole set of equipment undergoes non-woven fabric welding, earband welding, printing, half-folding, edge banding, rolling cutting and other integrated automatic folding production processes, which can process 3M 9001, 9002 and other folding masks. The raw materials selected according to product requirements can produce masks that meet different standards such as FFP1, FFP2, N95, etc. The entire production process does not require talents to participate, and the finished products are completed automatically.

Automatic unwinding-nose bridge feeding-ultrasonic welding-LOGO pad printing-ear strap welding-folding forming-ultrasonic welding cutting + finished product output

二、设备参数

1.适应产品规格要求:

1.1将3~6层PP无纺布、活性炭滤材料粘合,并剪切出折叠口罩本体。N95碟型口罩用于职业性呼吸防护,包括某些微生物颗粒(如病毒、细菌、霉菌、炭疽杆菌、结核杆菌等)。

2.设备基本配置参数

电源:AC220V 50HZ

气压:>0.6MPAA

效率:≈40pcs/min

良率:≥95%

功率:13KW

尺寸mm:9300L*1300W*1900H

2. Equipment parameters

1. Adapt to product specifications:

1.1 Bond 3 ~ 6 layers of PP non-woven fabric and activated carbon filter material, and cut out the body of the folding mask. N95 dish masks are used for occupational respiratory protection, including certain microbial particles (such as viruses, bacteria, mold, Bacillus anthracis, Mycobacterium tuberculosis, etc.).

2. Basic configuration parameters of the device

Power supply: AC220V 50HZ

Air source: 0.5 ~ 0.8MPA

Production efficiency: 40 ~ 50pcs / min

Production yield: ≥95%

Equipment size (mm): 9300 (L) * 1300 (W) * 1900 (H)

三、设备特点

1.原材料自动张力控制,保证原材料张力均衡。

2.光电检测原料,避免失误减少浪费。

3.变频控制,可根据需要调节设备运行速度。

4.自动化程度高、操作简单、仅需要放料和整理成品。

5.全机台采用钣金+铝合金结构,美观坚固不生锈。

6.模块化、人性化设计方便维护。