?

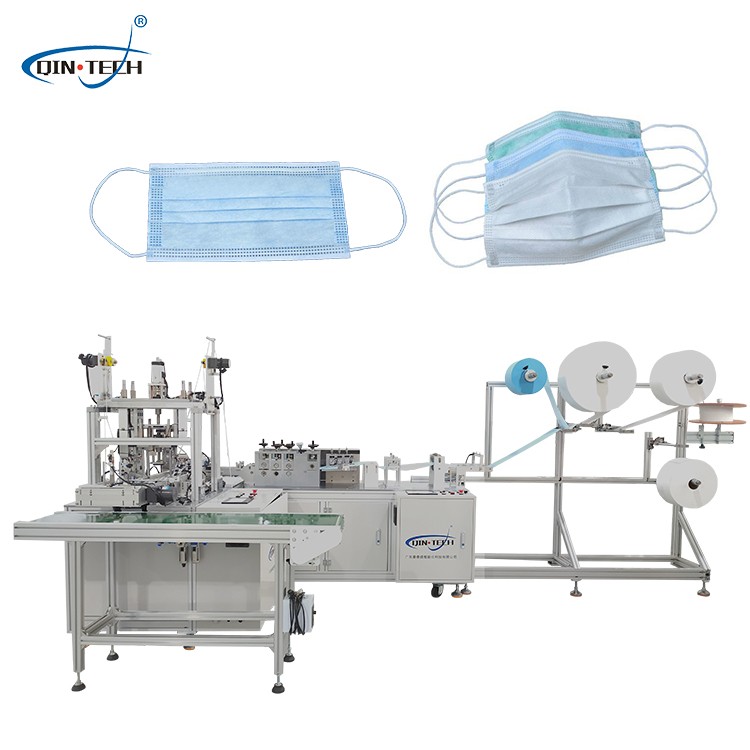

Equipment details display:

1. Unwind

2. Hemming

3. Insert the nose bridge

4. Ultrasonic welding

5. Earband welding

Adapt to product specifications

The production object is medical masks, which are mainly composed of three layers of non-woven fabrics. The outer layer is waterproof non-woven fabric, which is mainly used to isolate the liquid sprayed by the patient. The middle filter layer is polypropylene treated with electret Meltblown nonwoven fabric;

设备的基本配置参数

生产合格率:≥95% (原材料因素除外)

设备产能:90 pcs/min(±10%)

外形尺寸:4100(L)*2900(W)* 1990(H)

使用电压:AC 220V±10%/50HZ

设备功率:9KW

工作环境温度:10~35℃

工作环境湿度:5~35%HR

气压:0.5~0.6MPa

耗气量:300L/min

人员:1~2person

Basic configuration parameters of the device

Production pass rate: ≥95% (except for raw material factors)

Equipment capacity: 90 pcs/min (±10%)

Dimensions: 4100(L)*2900(W)* 1990(H)

Working voltage: AC 220V±10%/50HZ

Equipment power: 9KW

Working environment temperature: 10~35℃

Working environment humidity: 5~35%HR

Air pressure: 0.5~0.6MPa

Air consumption: 300L/min

Personnel: 1~2person

设备特点:

1、原材料自动张力控制。保证原材料张力均衡。

2、光电检测原料,避免失误减少浪费。

3、可生产三层口罩本体,出料成品输送带上平面长度为1200MM。

4、本设备有总量计数和分批计数功能,分批计数的数量可以任意设置。

5、全机台采用钣金+铝合金结构,美观坚固不生锈。

6、模块化、人性化设计方便维护。